June 11, 2021

Klein has issued a recall on some of their NCVT-1 non-contact voltage testers where an operator error (keeping the on/off button depressed) would erroneously indicate that the tool is ready to detect voltage by providing a green light at the tip of the tool when it in fact is not ready.

Schneider electric has recalled their Square D Brand General Duty 30 & 60A, 120/240 Volt 2-phase and 3-phase NEMA 3R Safety Switches. The power can stay on even when the switch is in the “OFF” position. This poses a serious shock or electrocution hazard. The recalled switches were manufactured from January 1, 2014 through January 18, 2018. See photo below for an example switch affected by the Safety Alert.

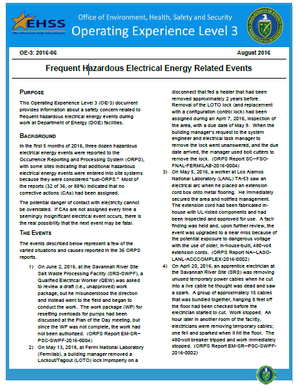

Schneider electric has recalled their Square D Brand General Duty 30 & 60A, 120/240 Volt 2-phase and 3-phase NEMA 3R Safety Switches. The power can stay on even when the switch is in the “OFF” position. This poses a serious shock or electrocution hazard. The recalled switches were manufactured from January 1, 2014 through January 18, 2018. See photo below for an example switch affected by the Safety Alert.  This Operating Experience Level 3 (OE-3) document provides information about a safety concern related to frequent hazardous electrical energy events during work at Department of Energy (DOE) facilities. In the first 5 months of 2016, three dozen hazardous electrical energy events were reported to the Occurrence Reporting and Processing System (ORPS), with some sites indicating that additional hazardous electrical energy events were entered into site systems because they were considered “sub-ORPS.” Most of the reports (32 of 36, or 88%) indicated that no corrective actions (CAs) had been assigned.

This Operating Experience Level 3 (OE-3) document provides information about a safety concern related to frequent hazardous electrical energy events during work at Department of Energy (DOE) facilities. In the first 5 months of 2016, three dozen hazardous electrical energy events were reported to the Occurrence Reporting and Processing System (ORPS), with some sites indicating that additional hazardous electrical energy events were entered into site systems because they were considered “sub-ORPS.” Most of the reports (32 of 36, or 88%) indicated that no corrective actions (CAs) had been assigned.